Products

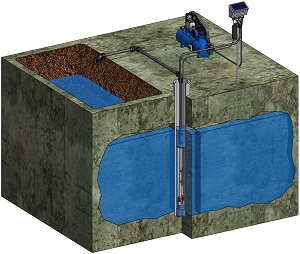

The Airwell system operation

- The pump body is being allowed to passively fill at the natural production rate of the well.

- Once the controller receives a "full" signal will pressurize the pump body with compressed air.

- The pump's content is being discharged through the discharge line.

- Once the controller receives an "empty" signal will discharge the pump body and let it start filling again.

Bottom filling pumps

The most common Airwell pumps. They are designed to pump water, contaminated, corrosive fluids from bores and they last for many years. |

|

Top filling pumps

These pumps are designed to fill from the top. They can pump to the surface all liquid above the top of the pump. As the water level drops to the top of the pump, the pump stops cycling. |

|

Sump pumps

These pumps are designed to be submerged in sumps and keep the water level as low as possible. |

|

Transfer pumps

The purpose of this pump is to get connected in series with the water line at one or more stages. It can give the water a total dynamic head of up to 80m at each stage. |

|

Floating pumps

This floating pump has been used for more than 20 years in multiple locations throughout Australia. The compact pump and controller design allows the system to be highly mobile in applications where a single pump may be moved for use in multiple locations. |

|

Evaporating pump

This floating pump has been succesfully used to increase the evaporating rate of leachate ponds. The filling procedure is quick thanks to the 8 inlet screens. With the 4 sprinklers attached at the corner posts, water is sprayed all arround at a big domed shape. All the sprayed tiny drops increase massively the liquid face in contact with the atmosphere, accelerating evaporating procedure. |

|

Oil and Gas pumps

Our top quality, minespec, high pressure pump designed to operate at 1500m depths. It can successfully replace the expensive to maintain progress cavity pumps, and make a low producing bore profitable for many years on. Safe and wear resistant construction are the main design aspects of this high pressure gas operated pump. Pumping flow rate can be remote controlled and adjusted to each bore's specific requirements. Coal fines and mud can be pumped without damaging the pump for a long period. |

|

Solar controller

This controller is ideal for use where a water bore is located far away from an electrical supply. Thanks to the integrated solar panel and battery combination it can control the Airwell pump operation and provide water supply 24/7. The amount of pumped water can be found with the integrated counter. |

|

Basic controller

This is a mains powered controller, so it has to be close to an electrical supply. If powered by a 8 x 8 skid controller can be intrinsic safe as an option. The amount of pumped water can be found with the integrated counter. |

|

S/S enclosure controller

This is a mains powered controller, so it has to be close to an electrical supply. It can control up to 3 pumps and 3 bubblers. The amount of pumped water can be found with the integrated counter. The water level in the bores can be found with the pressure gauges located inside the enclosure. |

|

Portable controller

This portble controller can be powered by mains (via transformer) or straight from the car battery (via cigarette lighter plug). The amount of pumped water can be found with the integrated counter. It also contains a dual timer which makes it suitable to operate a pump without using the probe signal. |

|

Skid controller

This controller is ideal for use where multiple water bores are located far away from an electrical supply. It can control up to: The above data can be monitored local on the PLC dispaly or remotely on your PC. Thanks to the integrated solar panel and battery combination it can control the Airwell pumps operation and provide water supply 24/7. Intrinsic safe and telemetry are available as an option.

|

|

|

|

|

Airwell is an official Pilot air compressor agent. For small scale projects (agricultural, environmental) stand alone reciprocating compressors can be supplied. For large scale projects (mining, landfills) screw compressors can be supplied inside shipping containers. |

The solar pumping proposal from Airwell consists of a galvanized steel frame and a Franklin solar powered submersible pump.

There are many frame types available to suit any combination of solar panels, according to the customer's needs.

The Franklin submersible is 100% controlled by a VSD optimised for solar powered systems. In order to improve efficiency, no batteries exist to the system.

In some specific cases an Airwell pumping system can be mounted instead of the Franklin one.

|

18 panel frame |

14 panel frame |

|

12 panel frame |

10 panel frame |

|

9 panel frame |

8 panel frame |

|

7 panel frame |

4 panel frame |

|

Assembly procedure |

Assembly procedure |

The Airwell Group sampling units are manufactured from the highest quality components and assembled in our Perth factory.

Why choose Airwell?

- Mine site approved constructions.

- Choice of Airwell sampling units that meet your requirements.

- Up to 15-20 bores sampled in a day depending on bore depth, yield and distance between bores.

- Low risk of contamination with coaxial discharge, airline and cable system.

- No minimum flow rate in low flow applications.

- High grit tolerance with no parts likely to be damaged by high grit bores.

- 1¾” (45mm) dia x 1 or 2m long sampling pump goes down 50mm casing diameter.

- 3½” (89mm) dia x 1 or 2m long sampling pump for larger casing diameter and higher flow rates.

- All pumps are interchangeable on our standard hose reel system.

- Silenced air compressor and hydraulic pack.

- Reduced OH&S issues with no manual handling required to raise or lower pumps.

- Electrical safety with system requiring no high voltages and no trade licences to operate or maintain.

- Comprehensive training provided.

Notes:

- Lowering or raising of the pump is done mechanically.

- Arm lifting, lowering, swiveling is done mechanically (depending on model).

- By using the coaxial hose setup, the single R7 1” I/D hose eliminates the possibility of contamination being trapped within multiple hose bundles bound together with duct tape or cable ties.

- Hose lengths are made to customer requirements from 30 metres to 110 metres in length.

- Disinfecting the pump and internals of the hose between bores is done by simply placing the pump in a container with a Decon 90 solution or similar.

|

|

|

|

|

|

Airwell's portable bubbler tube system allows to take accurate fluid level readings from the surface. The system can be easily installed on any bore and even in pond or tank monitoring applications. |

|

Stuffing box for sealed bore drilling. |

|

|

Bore casing reducing sleeves. |

|

|

Overhead pipework to bypass a footpath. |

|

|

Wellcap. |

|

|

Silt interceptor. |

|

|

Solar trailers with DC compressors and PLC units for automatic pollution recovery. |

|

|

Submersible pump controllers with VSD and flow meter. |

|

|

Controller skids for Oil & Gas wells deliquification. |

Quality

Quality Environment

Environment Safety

Safety